Water Quality Analysis for Steam-Based Sterile Processing Devices

The Importance of Water Quality for Steam Sterilization

As an autoclave service provider for over three decades, Minnesota Medical has identified that a frequent single point of failure facing many steam sterilizer end users is often the quality of water being supplied to the steam generation source. Facilities that overlook the quality of their feed-water sources run the risk of increased down time and higher repair bills due to the unforeseen damage caused by untreated water wreaking havoc on boilers, heating elements, valve assemblies and other critical parts throughout the system.

How Subpar Water Leads to Equipment Issues

Why does subpar water quality lead to issues in steam sterilization systems? Sterilizers themselves are complicated pieces of equipment with many components varying greatly between manufacturers, designs and modalities. But the chemical properties imbued and shared between the physical states of water is one thing that ties all forms of sterilizer performance together. When water is boiled, any particulates suspended in its liquid form are generally left behind as a substrate within the vessel which the boiling reaction occurs. In the context of a steam generator, boiler system, or autoclave chamber, this means that untreated and contaminated water will leave a literal footprint of its presence across the system.

The Perils of Scale Buildup

The most common form of this “footprint” is scale – a buildup of hard deposits, namely calcium and magnesium, that forms on the interior components of steam devices, primarily boilers. Left untreated over time, scale buildup kills heat-transfer efficiency, leading to increased energy consumption requirements, reduced heating element component lifespan, and higher run-time costs. Left for too long, scale buildup can lead to overheating, melted heater wires and contacts, and in the worst cases, catastrophic failures.

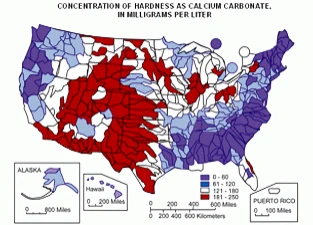

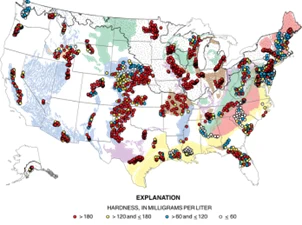

Optimal Water Quality Parameters for Sterile Processing

What water quality recommendations exist to prevent such issues? Most bulk sterilizer OEMs agree that 50 to no more than 120 mg/L is the preferred range for the presence of Total Dissolved Solids (TDS) within unit feedwater sources. Within that range, the total hardness (in mg/L of CaCO3) should fall under 60. On average, national public water sources are anywhere between 110-150 mg/L in total hardness. Because of this, some form of water treatment should always be taken into consideration when installing and operating steam generation systems.

The Need for Water Treatment

The Worsening State of America’s Water Supply

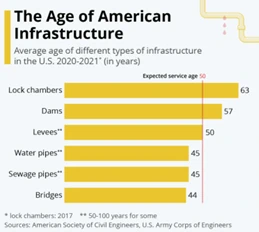

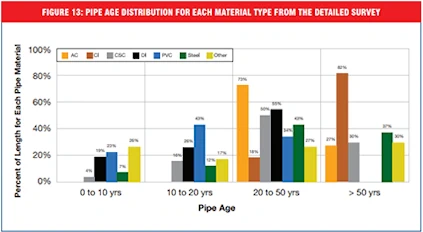

Why is water quality of increasing concern now? Can’t we count on public infrastructure improvement as time moves on? Current research and data would suggest otherwise. As American water distribution and treatment infrastructure ages, it is a known fact that the quality of our public water supply will diminish unless large public level infrastructure investments are made. Per a joint ASCE (American Society of Civil Engineers) and USACE (United States Army Corps of Engineers) study in 2020, the average age of water supply infrastructure across America is 45 years or older. As the clock keeps ticking, this infrastructure will continue to leach and degrade, adding more particulate contamination to the water supply.

Aging Infrastructure and Funding Gaps

How does this impact the future state of water quality? Over the last decade, there is a running national funding gap of over $105 billion with regards to civil water improvement projects (per ASCE, 2017). Furthermore, this aging infrastructure will degrade even faster as water supply demands increase exponentially, exacerbated by population growth and the ever-increasing frequency of extreme weather events (i.e. drought, forest fires, etc). All analytics and research indicate that year-over-year, addressing water quality concerns at the public, nationwide level are becoming increasingly untenable from a scope and cost perspective.

Mitigating Water Quality Risks

What options exist for mitigating these risks in lieu of public infrastructure improvements? Multiple private-party water quality systems exist and are widely available to any level of consumer across the country. The key for sterile processing steam system end users is to identify the right system for their unit characteristics and design parameters.

Water Softening Systems

At the most widely available and lowest total cost end of the spectrum are water softening systems. These systems are highly effective in addressing water hardness (i.e. calcium and magnesium) concerns, but do not address overall TDS. Water softeners utilize resin beads to conduct an ion exchange with calcium and magnesium mineral compounds. These minerals are replaced with sodium or potassium ions. Because of this, water softeners are generally only a stopgap measure to minimize calcium and magnesium specific scale buildup, but not fully address residual substrates left behind during the boiling reaction. These systems are usually specified and quoted based on the amount of water consumed on a daily interval, and the overall hardness of the incoming water source.

Reverse Osmosis (RO) Systems

Reverse Osmosis (RO) systems are another commonly available option. Slightly more expensive than water softeners due to system complexity and the required replacement filters, RO systems utilize multiple layers of filtration to remove the majority of particulate contaminates from a water source. There are a wide array of filter options available to address specific contaminants, and on average a well-researched and implemented RO system will address 95% of all TDS from an incoming feed source. But as with all equipment with consumable components such as filters, regular maintenance and inspections are critically important in ensuring the system is operating as designed. As with water softening systems, all RO systems need to be planned and installed with the appropriate water volume consumption rates and total hardness in mind beforehand.

Water Distillation Units

Another form of water quality improvement system available to end users are water distillation units. Water distillers purify water by boiling the feed water supply, capturing the steam, and then condensing it back to liquid form for usage. However, distillation is usually not the best methodology for purifying water for steam system usage. For one, in it far more expensive to create large amounts of distilled water than it is to create the same amount of RO water in the course of the day, mainly due to the energy draw from the distillers heating elements. Furthermore, a distiller itself will require some form of water treatment on the infeed to prevent scale buildup from occurring, no different than the boiler or steam generator on an autoclave. For that reason, it is usually more cost effective to select a capable enough pre-filtration source to directly supply an autoclave steam generator itself versus also investing in a supplementary distillation system.

Deionization (DI) Water Purification

The final system to be discussed with regards to water quality improvement are deionization (DI) water purification systems. The most expensive offering of the other options reviewed, these ultrapure systems pass water through ion exchange resins, similar to water softeners. However, the resins in DI systems are far more effective and aggressive, replacing all particulate ions with hydrogen and hydroxide ions – this effectively removes all contaminants from the feedwater source. As opposed to the 95% effectiveness on average of RO systems, DI systems can achieve greater than 99.9% purity. However, there are drawbacks to utilizing such highly purified water. Due to the high levels of dissolved oxygen and the lack of buffer ions such as chloride in DI water, the dezincification of brass alloys immersed in DI water occurs much more rapidly. Therefore, only steam sterilization systems utilizing stainless steel boiler, valve and chamber components should utilize DI water as its feed source. Otherwise, the end user can expect far more premature replacement of vital system components over time.

Safeguarding Steam Sterilization Equipment

In summary, facilities utilizing steam-based sterilization devices should consider the means at their disposal to mitigate the risks of untreated water damaging their capital equipment. All indicators demonstrate that as public water infrastructure degrades over time, the performance and lifespan of steam-generating devices will decrease as well unless measures are taken to address water quality issues. In most cases, RO systems are the frontrunner for the most commonly available, cost effective, and results oriented option for end users, but depending on the specific case usage, other systems remain available for consideration.

[magnet-genius id=”1″]